Manufacturing

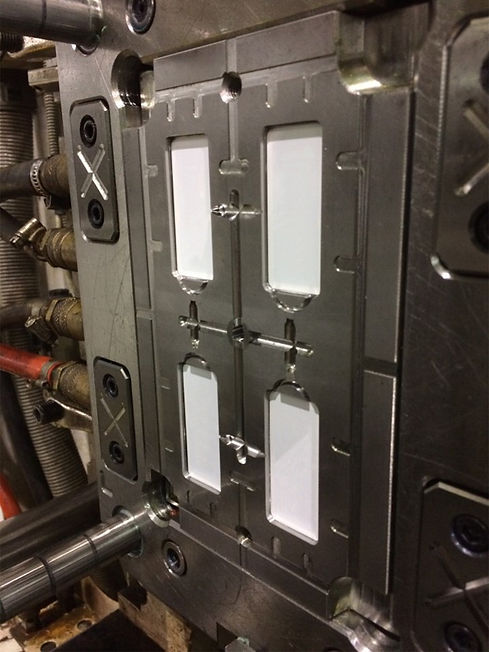

Where products begin their journey and are ready to be transported around the world. Our experienced team carefully select and work closely with our manufacturing partners to deliver new exciting products into the hands of the users. Each manufacturer has their own valuable skills and experience to bring to the project and are key partners to make the products highly successful. Our extensive supplier network allows us to find the most suitable for the job such as finding an injection moulder that specialises in electronic overmoulds, medical grade parts, optical lenses, large components etc. With suppliers mainly based in the UK and China we can cater for different requirements and discuss the different options to find the right balance.

What is manufacturing?

Manufacturing is the creation products with the help of machines, labour, tools, chemicals etc. Typically, raw materials are taken and transformed into a component on a large scale. Processes are designed and controlled to provide the quality and consistency needed. Part prices are normally less than prototypes but tend to have higher start up costs.

As a rule of thumb, production tooling has a payback period of around 1-3 years. This is paid back via the reduced part costs compared to the existing method and can sometimes even be recovered within the first couple of batches.

Manufacturing methods:

-

Injection Moulding

-

Low pressure moulding

-

Vacuum moulding

-

Blow moulding

-

Compression Moulding

-

Rotational moulding

-

Cable assembly

-

Machining

-

Extrusion

-

Die casting

-

3D Printing

-

Laser cutting

-

Forging

-

Stamping

-

Electroplating

-

Sheet metal fabrication

-

These methods offer different advantages which can depend on factors such as materials, volume, precision, time and cost. Most products may use a range of these methods to complete the assembly.